Our Mission:

Tailored Manufacturing Solutions for Composites

Terzima Composites is focused on bridging the gap of materials and manufacturing methods to create and maintain high performance parts. With experience driving technology and manufacturing readiness levels (TRL/MRL) from early development (2/3) to production (7/8), Terzima is an ideal manufacturing partner for new material development. Current key focus areas are in composite repair and early production capabilities with goals to expand to high rate manufacturing.

Our Capabilities

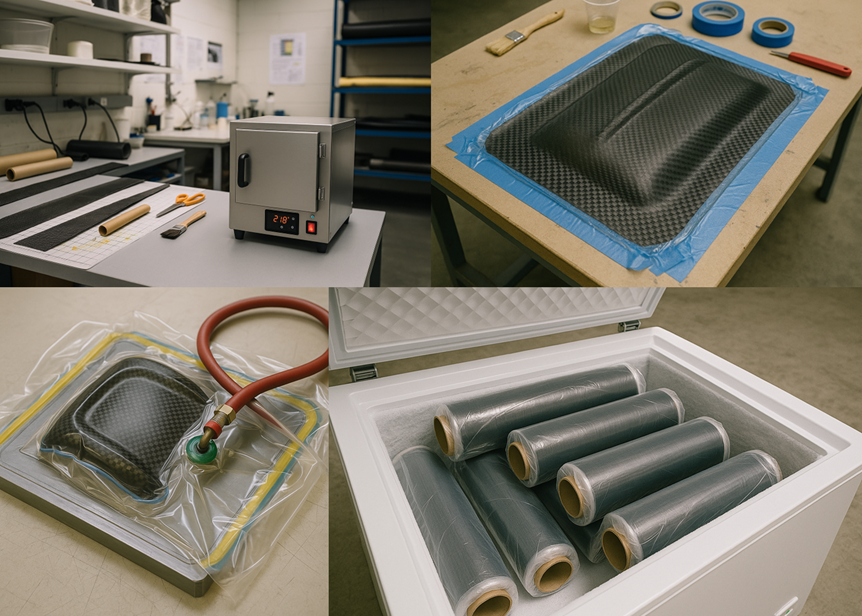

Out-of-Autoclave Oven Curing

Cleanroom Layup and Finishing

Custom Tooling & Mold Development

Rapid Prototyping

Advanced Material Development

Short-Run and Prototype Production

Additive Manufacturing

Material and Innovation

At Terzima, we are working on cutting-edge vitrimeric resins and reinforcement systems tailored for demanding applications.

We offer:

- Composite repair for defense and commercial applications

- Composite part prototyping services

- Low batch production of composite parts (<10)

- Material development and characterization for new composite materials

Why Terzima Composites?

Aerospace Standards

Cleanroom layup, precise curing, and QA built in.

Fast Turnaround

Work fast without sacrificing quality.

Small Batch Friendly

Ideal for R&D teams, startups, and prototype work.

Contact Us

Terzima Composites

Composite Repair and Material Development

Contact us to meet your composite manufacturing needs